Angle iron cutting machine 45 degree punch machine

Basic Info

Model No.: TAPM1412

Product Description

Angle iron cutting machine 45 degree angle cutting machine

CNC Punching, Marking and Cutting Machine for Angles Model TAPM1010 is a CNC Angle Line Equipment. It mainly used for angle Punching, Marking and Cutting. It is wildly used in Communication Tower, power transmission tower and other industries.

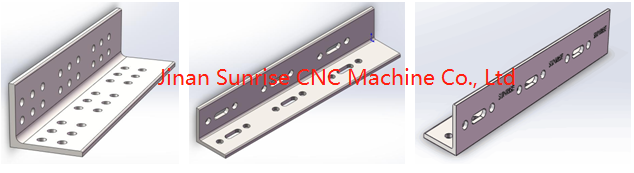

This CNC angle line machine is a small model to process angle, the angle size is from 40*40*3mm-100*100*10mm. The material of the angle will be Q345. The punching force is 600/1000KN. There are two / Three punching head in each side of the CNC angle line machine.

There are totally three CNC axes for the angle processing machine. This angle line is single blade cutting (SCM also has double blade cutting angle line machine).

This kind of angle punching, marking and cutting machine can process max. length 10 or 12 meters raw angle. The max. length of finished angel is 8 m.

The layout of the CNC angle machine can be A type layout and B type layout. The customer can choose according with their workshop.

The machine is the special equipment used for angle steel punching, marking & shearing in the field of angle steel tower industry, mainly composed of transverse conveyor, rotating loading system, infeed conveyor, CNC infeed carriage, punching unit, marking unit, cutting unit, unloading conveyor, as well as hydraulic, electrical and pneumatic systems etc.

Product Feature:

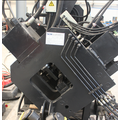

1. Adopt CNC technology, servo motor infeeding, with high efficiency, stable workpiece precision. Key hydraulic, pneumatic and electric parts all imported.2. There are three sets of punch and die on each side which can install three kinds of punches with different diameters, can process all holes once time.

3. Computer with Chinese/English interface, easy operation, and can display the drawing of workpiece. Easy programming, can manual programming and also can use the program generated by lofting software. It can read NC.1 files generated by TEKLA software.

4. CNC infeed carriage is driven by servo motor. The photoelectric encoder feeds back the information. Closed loop control to ensure high positioning precision.

5. All marking, punching and shearing in automatic completeness, all finished angles can be unloaded by pneumatic turnover device so as to lighten the working strength.

6. The control system consists of the host computer, servo motor, PLC, external examination sensors, etc. Just input the dimension of workpiece, the processing will be created. Furthermore, the program can be stored, selected, displayed and communicated as per the workpiece No.

7. Marking unit adopts closed frame with good rigidity. Four groups of character boxes are fixed on the marking unit which can be selected by program.

8. TAPM2020A is single blade shearing, no scraps. TAPM2020 and TAPM2020C is enhanced model, the punching, marking and shearing cylinders are bigger;

9. With avoided shearing functions, so as to process fixed-length angles.With function of self-diagnosis for failures.

| Model | TBL2020 | TAPM2020 | TAPM2020A |

| Angle size (mm) | 50х50х3~200х200х20 | 63х63х4~200х200х20 | 63х63х4~200х200х20 |

| Max. Punching (dia. х thi.) (mm) | Φ26х20 | Φ26х20 | Φ26х20 |

| Punching force (kN) | 1000 | 1200 | 1200 |

| Marking force (kN) | 800 | 1030 | 1030 |

| Shearing force (kN) | 1400 | 2100 | 4300 |

| Max. length of blank (m) | 14 | 14 | 14 |

| Max. length of finished (m) | 12 | 12 | 12 |

| Punches per side | 3 | 3 | 3 |

| Group of Marking letters | 4 | 4 | 4 |

| Dimension of letter (mm) | 14×10×19 | 14×10×19 | 14×10×19 |

| CNC axes | 3 | 3 | 3 |

| Shearing mode | Double blade cutting | Double blade cutting | Single blade cutting |

| Feeding speed of angle (m/min) | 60 | 60 | 60 |

| Programming mode | Lofting software or instruction program | ||

| Overall dimensions (mm) | ≈32000×7000×3000 | ≈32000×7000×3000 | ≈32000×7500×3000 |

| Gross Weight of machine (kg) | ≈16500 | ≈17000 | ≈17500 |

| Total power (kW) | About 35 | About 40 | About 40 |

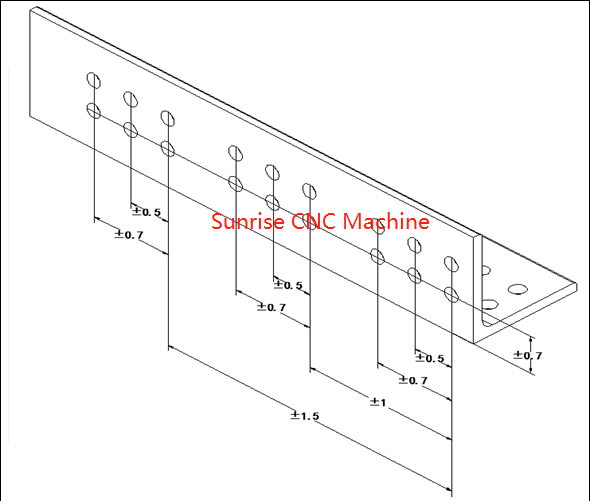

| Processing precision (The allowable tolerance): | ||

| 1. | Two adjacent hole deviation of the same group | ±0.5mm |

| 2. | Two not adjacent hole deviation of the same group | ±0.7mm |

| 3. | Hole deviation of two adjacent group | ±1mm |

| 4. | Stadia (Distance from central of hole to edge ) | ±0.7mm |

| ||

Main Components List:

| No. | Name | Brand | |

| Main Electric Components | |||

| 1 | PLC | Japan YOKOGAWA | |

| 2 | Servo Motor | Japan YASKAWA | |

| 3 | Servo Driver | ||

| 4 | Business Computer | China Lenovo | |

| 5 | Photoelectric Switch | AUTONICS | |

| 6 | Low-voltage electrical parts(Switches,Push button, Breaker,Indicator light, Contactor switch and so on) | German SIEMENS | |

| 7 | Proximity Switch(N.O) | AUTONICS | |

| 8 | Proximity Switch(N.C) | AUTONICS | |

| 9 | Power Supply | China Aerospace | |

| Main Hydraulic Components | |||

| 1 | Hydraulic Valves | Italy ATOS | |

| 2 | Vane Pump | America DENISON | |

| Main Mechanical Components | |||

| 1 | Linear Slide | HIWIN | |

| 2 | Ball Screw | HIWIN | |

| Main Pneumatic Components | |||

| 1 | Punching Unit | Padding Block Cylinder | Japan SMC or AirTAC |

| 2 | Magnetic Switch | Japan SMC or AirTAC | |

Spare parts list:

| No | Name | Material | Qty. | Remark |

| 1 | Punch head (Ф17.6, Ф21.6, Ф25.6) | T10A | 12 | Including installed in machine |

| 2 | Cavity die (Ф18.7,Ф19.2,Ф22.7, Ф24.6,Ф26.7,Ф28.6) | T10A | 24 | Including installed in machine |

| 3 | Upper blade | 9CrSi | 2 | Including installed in machine |

| 4 | Short nether blade | 9CrSi | 4 | Including installed in machine |

| 5 | Long nether blade | 9CrSi | 4 | Including installed in machine |

| 6 | Punching die base | ZG45 | 7 | Including installed in machine |

| 7 | Punch head pole | T10A | 7 | Including installed in machine |

| 8 | Punching screw nut | 40Cr | 7 | Including installed in machine |

| 9 | Upper jaw | T10A | 2 | Including installed in machine |

| 10 | Nether jaw | T10A | 2 | Including installed in machine |

| 11 | Character box | T10A | 4 | Including installed in machine |

| 12 | Character | T10A | 1 set | Including installed in machine |

| 13 | Proximity switch | Normal open | 1 | AUTONICS |

| 14 | Proximity switch | Normal close | 1 | AUTONICS |

| 15 | Photoelectric switch | 1 | AUTONICS | |

| 16 | Charge nitrogen tool | CQJ-16 | 1 set | |

| 17 | O ring | 2 sets | ||

| 18 | Spanner for punch head | 1 | Manufacturer made | |

| 19 | Spanner | 2 | Manufacturer made | |

| 20 | Tools with equipment | 1 set | ||

| 21 | Springs | 1 set | ||

| 22 | Standby paint | 2 pail | 1pail for main color and 1pail for warning color | |

| 23 | Operation Manual & Attached Illustration | 2 sets | ||

More information and competitive price inquiry let us know:

Product Categories : Punching Machine > Angle Punching Machine