Q35y Series Hydraulic Ironworkers for Multi-Function (Q35Y-25 Q35Y-30)

Basic Info

Model No.: Q35Y-25, Q35Y-30, Q35-40, Q35Y-50

Product Description

Model NO.: Q35Y-25, Q35Y-30, Q35-40, Q35Y-50 Layout: Horizontal Automatic Grade: Automatic, Manual, Semi-Automatic Design: Two Oil Cylinders Ceritifcate: CE. ISO9001 Trademark: JSTMT Origin: CHINA Customized: Customized Cutting Material: Carbon Steel Power Source: Hydraulic Pressure Color: Red or Blue Model: Q35y-25(120ton) Specification: CE HS Code: 84624900 Hydraulic Iron worker(Q35YSeries), Punching and Shearing Machine for Multi-function -China Supplier

* The Hydraulic Iron worker widely used in metal structure processing, steel mold, vehicles, Tower Rack, Tele-communication Rack, Ship Building, Bridge.

* It adopt hydraulic driving system for various metal plate cutting, square bar, Round bar, angle,channel and joist, punching and notching.

The hydraulic system and Electrical component are adopt Big brand, with stable characters and safe working environment.

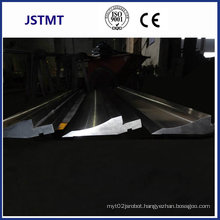

* Functions:

Shearing, Sectional Cutting(squar, round, Channel, Joints, Equal angle). Notching and Punching(RD.SQ.RE.OB).

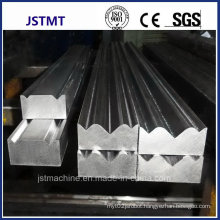

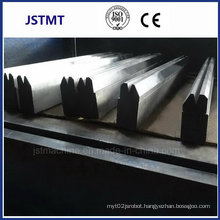

* Iron worker withTools:

Each standard one set of tools.

Option: Different sizes for RD. SQ. RE. And special joints. Louver, muti-V bending tools

* China Pump, Simens electrical, Imported Searling rings with CE qualified.

* Can option with:

1. Two cylinders working same time without interference

2. Hydraulic System Cooling system

3. CNC automatic positioning and feeding system

*Model specifications: Q35Y-16, Q35Y-20, Q35Y-25, Q35Y-30

Products & tool references:

Parameters:

Contact us if you need more details on Ironworker. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Punching and Shearing Machine、Hydraulic Ironworker. If these products fail to match your need, please contact us and we would like to provide relevant information.

* The Hydraulic Iron worker widely used in metal structure processing, steel mold, vehicles, Tower Rack, Tele-communication Rack, Ship Building, Bridge.

* It adopt hydraulic driving system for various metal plate cutting, square bar, Round bar, angle,channel and joist, punching and notching.

The hydraulic system and Electrical component are adopt Big brand, with stable characters and safe working environment.

* Functions:

Shearing, Sectional Cutting(squar, round, Channel, Joints, Equal angle). Notching and Punching(RD.SQ.RE.OB).

* Iron worker withTools:

Each standard one set of tools.

Option: Different sizes for RD. SQ. RE. And special joints. Louver, muti-V bending tools

* China Pump, Simens electrical, Imported Searling rings with CE qualified.

* Can option with:

1. Two cylinders working same time without interference

2. Hydraulic System Cooling system

3. CNC automatic positioning and feeding system

*Model specifications: Q35Y-16, Q35Y-20, Q35Y-25, Q35Y-30

| Description | Unit | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | |

| Shearing | Flat bar thick x wide | mm | 16x250 | 20x330 | 25x330 | 30x355 |

| Max Capacity | mm | 8x400 | 10x480 | 16x600 | 20x600 | |

| Section Cutting | Square bar | mm | 40 | 50 | 50 | 55 |

| Round bar (Dia) | mm | 45 | 50 | 60 | 65 | |

| Channel (type) | mm | 120 | 160 | 200 | 280 | |

| Joists (type) | mm | 120 | 160 | 200 | 280 | |

| Equal at 90 | mm | 125x12 | 140x12 | 160x14 | 180x16 | |

| Notching | Thickness | mm | 8 | 10 | 10 | 12 |

| Width | mm | 80 | 80 | 80 | 80 | |

| Depth | mm | 100 | 100 | 100 | 100 | |

| Punching | Thickness | mm | 16 | 20 | 25 | 26 |

| Max Diameter | mm | 25 | 30 | 35 | 38 | |

| Throat Depth | mm | 300 | 355 | 406 | 600 | |

| Max Stroke | mm | 80 | 80 | 80 | 80 | |

| Stroke Number | 25mm | 8-22 | 8-22 | 8-22 | 8-22 | |

| Tensile Strength (Times/Min) | | 450 | 450 | 450 | 450 | |

| Oil volumn,46# | L | 60 | 80 | 120 | 210 | |

| Motor Power | kw | 4 | 5.5 | 7.5 | 11 | |

| Overall size, Lx W x H | mm | 1640x730x1770 | 1860x900x1900 | 2355x960x2090 | 2680x1040x2300 | |

| Machine Weight | kg | 1700 | 2300 | 4300 | 6800 | |

Products & tool references:

Parameters:

| Description | Unit | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | |

| Shearing | Flat bar thick x wide | mm | 16x250 | 20x330 | 25x330 | 30x355 |

| Max Capacity | mm | 8x400 | 10x480 | 16x600 | 20x600 | |

| Section Cutting | Square bar | mm | 40 | 50 | 50 | 55 |

| Round bar (Dia) | mm | 45 | 50 | 60 | 65 | |

| Channel (type) | mm | 120 | 160 | 200 | 280 | |

| Joists (type) | mm | 120 | 160 | 200 | 280 | |

| Equal at 90 | mm | 125x12 | 140x12 | 160x14 | 180x16 | |

| Notching | Thickness | mm | 8 | 10 | 10 | 12 |

| Width | mm | 80 | 80 | 80 | 80 | |

| Depth | mm | 100 | 100 | 100 | 100 | |

| Punching | Thickness | mm | 16 | 20 | 25 | 26 |

| Max Diameter | mm | 25 | 30 | 35 | 38 | |

| Throat Depth | mm | 300 | 355 | 406 | 600 | |

| Max Stroke | mm | 80 | 80 | 80 | 80 | |

| Stroke Number | 25mm | 8-22 | 8-22 | 8-22 | 8-22 | |

| Tensile Strength (Times/Min) | | 450 | 450 | 450 | 450 | |

| Oil volumn,46# | L | 60 | 80 | 120 | 210 | |

| Motor Power | kw | 4 | 5.5 | 7.5 | 11 | |

| Overall size, Lx W x H | mm | 1640x730x1770 | 1860x900x1900 | 2355x960x2090 | 2680x1040x2300 | |

| Machine Weight | kg | 1700 | 2300 | 4300 | 6800 | |

Product Categories : Combined Punching And Shearing Machine

Premium Related Products

Other Products

Hot Products

Iron Worker Combined Iron WorkerIron Worker Combined Punching MachineMechanical Gear Shaping Machine (B6050)Hydraulic Notching Machine for Variable Angle (QX28Y-6X200)Universal Millling Machine Machine, 4vh4-Cloumn Hydraulic Oil Press Machine (YQ32-160)Steelworker Machine, Steel Ironworker, Metalworker Machine for Stainless (Q35Y-30)Thick Punch Dies for Amada Punch MachineCNC Turret Punching Machine (VT300)Sheet Metal Nc Shearing Machine with Laser (QC12K-10X3200)Lathe Machine, Heavy Duty Lathe Machine, Horizontal Lathe (CW61110, 1100-3000mm)Amada Goose Neck Punch Press Brake Tooling for Bending Machine160 Ton Pneumatic Power Press, C Frame Power Press (JH21-160)Metal Steel Sheet Plate Cutting CNC Hydraulic Guillotine Shearing Machine (QC12Y-12X3200)CNC Hydraulic Press Brake, Hydraulic Bending Machine, CNC Press Brake (125T 3200 DA66W 4+1axes)Amada CNC Press Brake with Italy Mpf Dro (APB63.31)